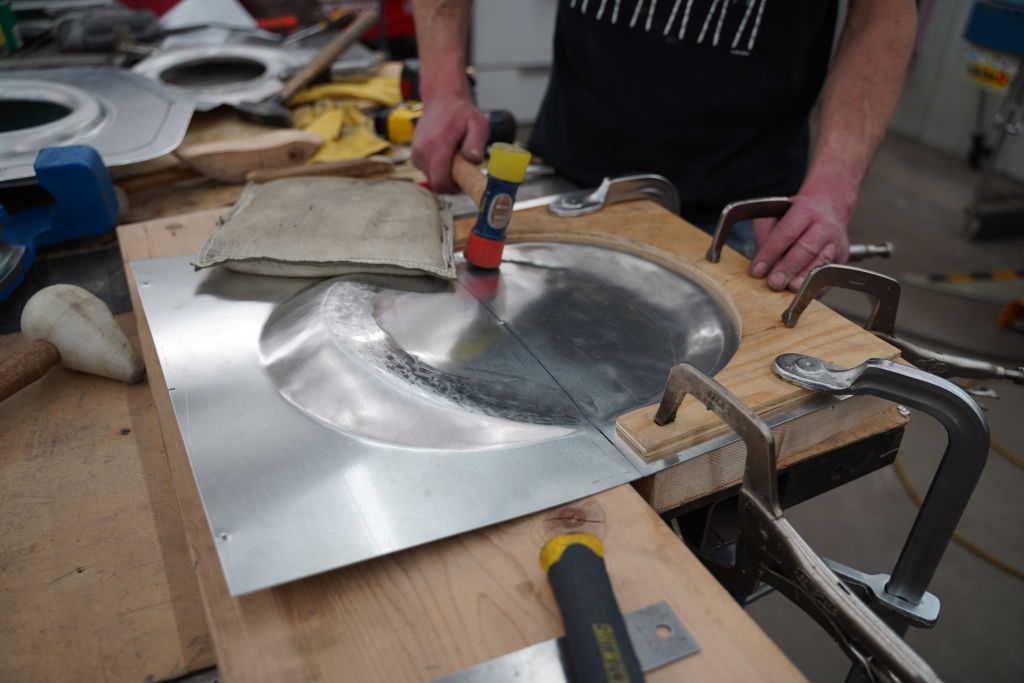

MCR hand fabricates an aluminum version of a T/A shaker.

One of the significant differences between a factory stock restoration and a custom build (on any level) is that whenever there is a departure from the original design there is always the possibility that that departure could affect other areas of the build. In other words, an update or change in one area may force changes in others to accommodate it.

The difference between having skills vs. having experience is knowing in advance that if this is done then that will also need to be changed.

This is never an issue with a project that MCR builds from start to finish both because of their 30+ years of experience (actually a lot more than that if you count the collective experience of all the employees) but also because every phase of the build is mocked up to insure that everything is working together as expected. Should the unexpected arise, catching it early in the process makes the solution much easier.

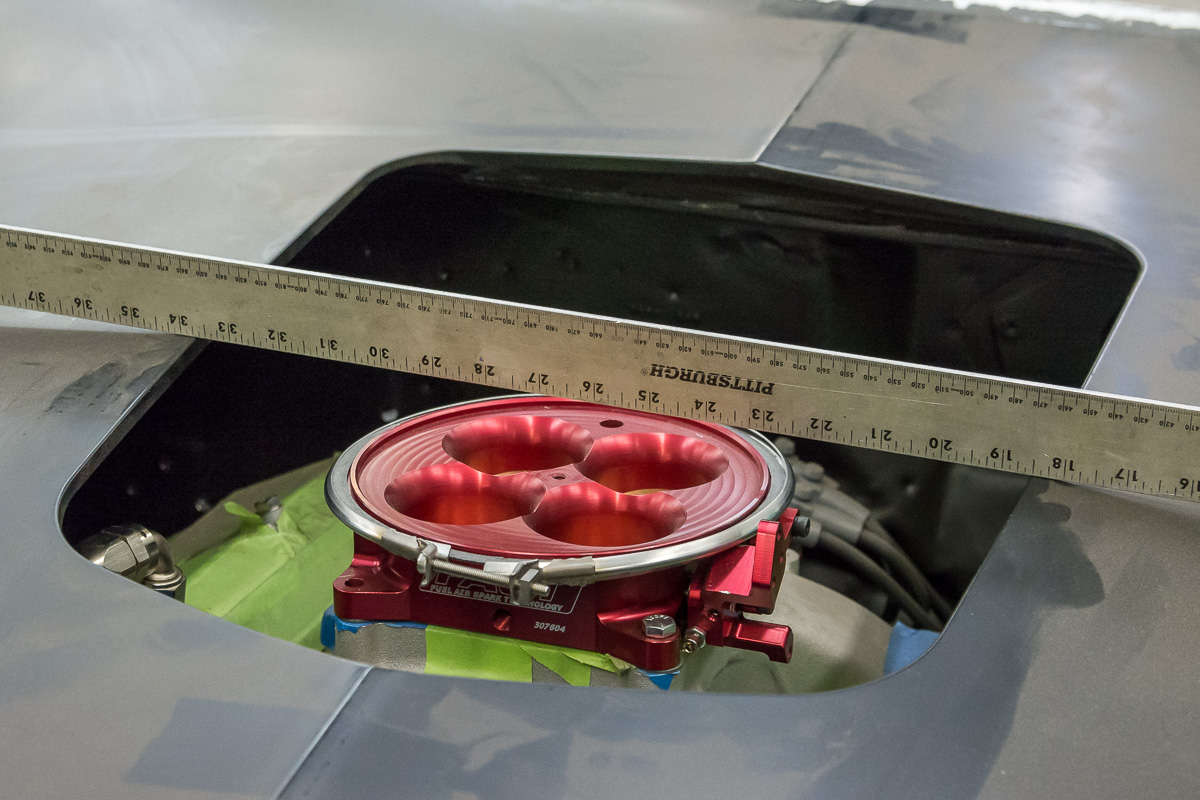

MCR recently had an opportunity to show off their custom fabrication skills to solve a compatibility issue on a 1980 Trans Am. The owner had his engine built off-site with a taller than stock intake topped with a FAST 2000 CFM throttle body. Wanting to keep his original T/A shaker scoop, the engine builder supplied an adapter to fit the scoop to the taller intake, this was not however made for extra large 7-3/6″ throttle body, nor did it have clearance for throttle linkage or sensors.

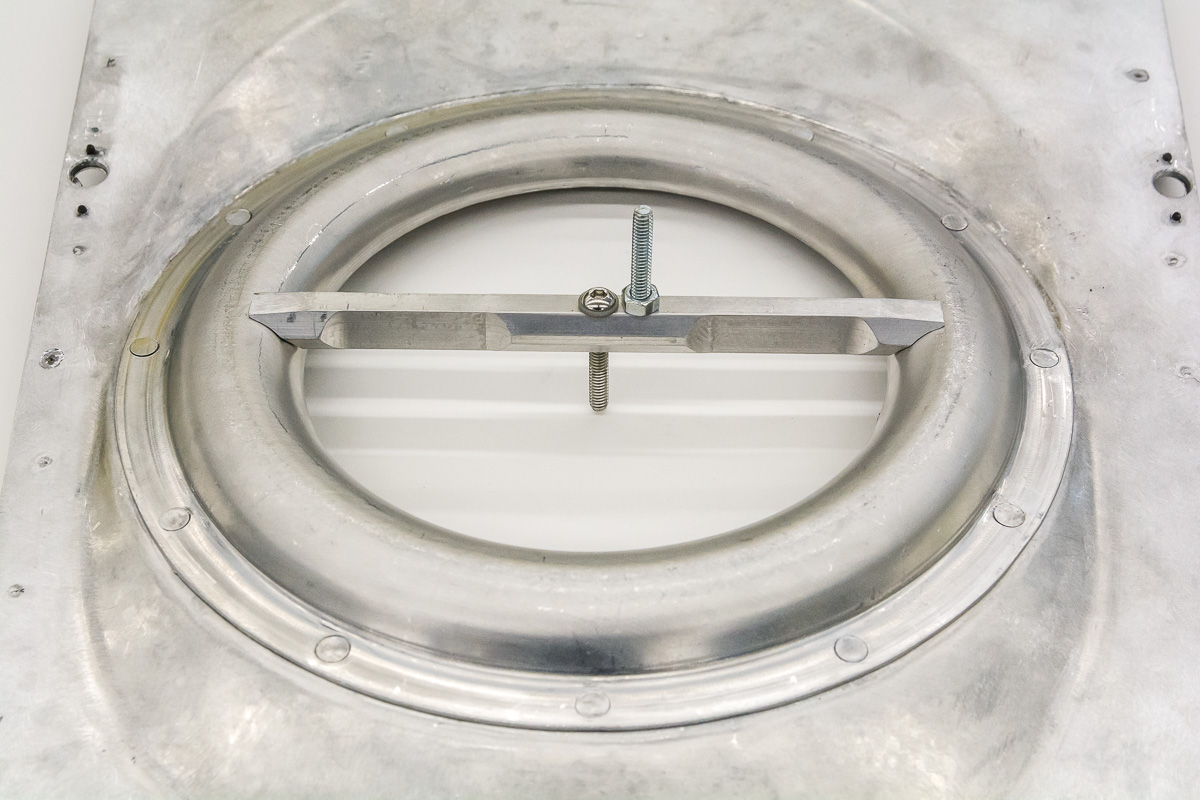

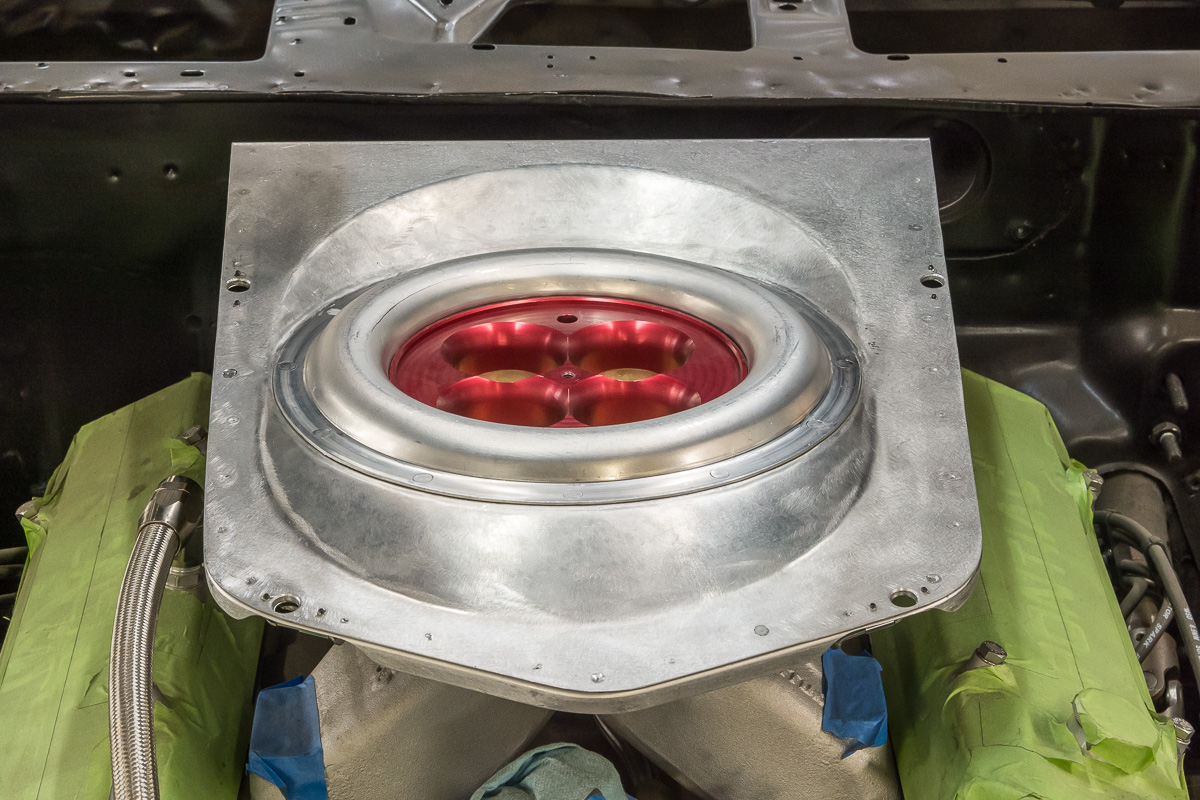

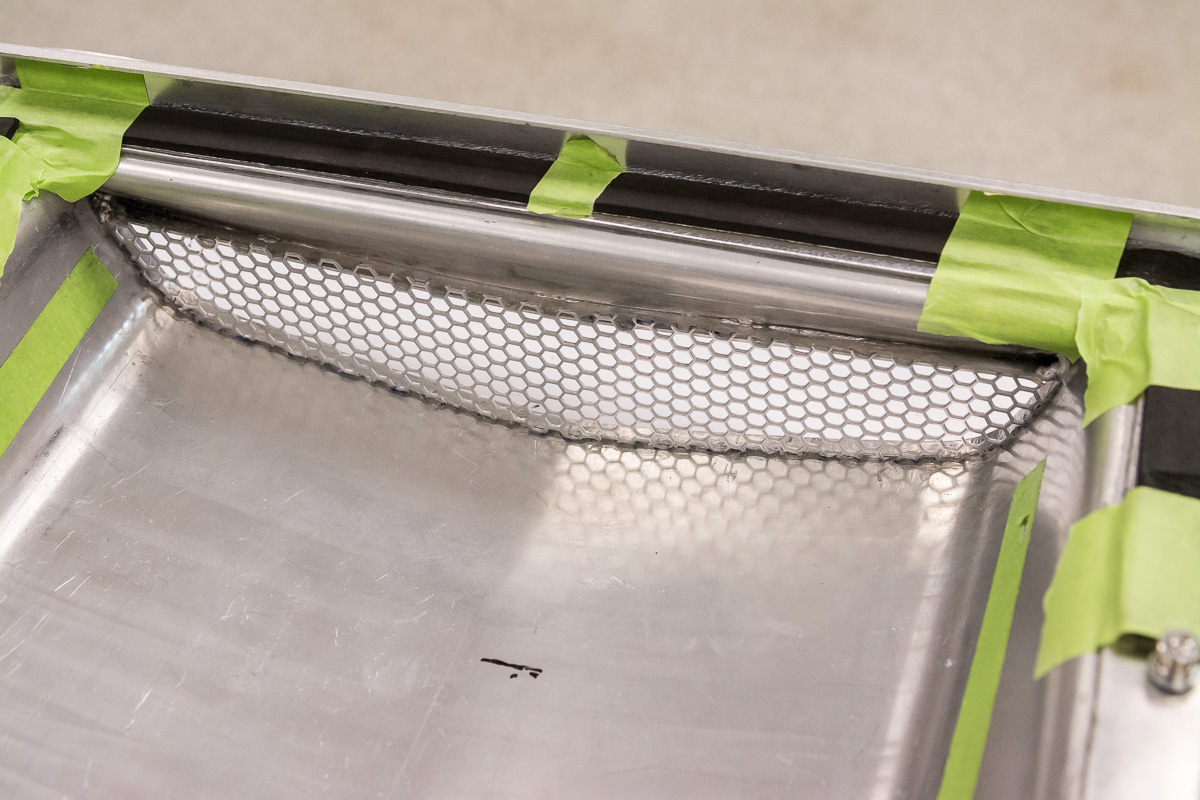

The solution was to hand fabricate a new scoop using the original as pattern. The new scoop had to accommodate three major changes where the custom engine differed from the factory version. First the scoop had to allow for the overall taller height of the throttle body. It also had to fit the much wider mouth of the FAST throttle body over that of the original carb. Then it had to have the proper amount of offset built in to keep the scoop centered in the hood opening and all this while providing a good path for air to flow into the engine.

The result is a one-off hand formed aluminum scoop that, once painted, will be indistinguishable from the factory fiberglass scoop.

Sources

| FAST, Fuel Air Spark Technology | Fuel Air Spark Technology |

| Muscle Car Restorations, Inc. | https://www.musclecarrestorations.com |